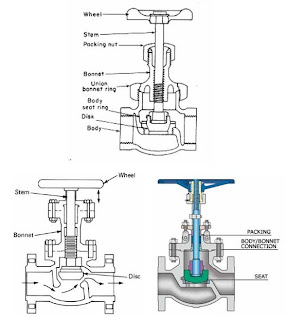

Figure 2 Globe valve (a) the structure of a small valve (bottom) structure of the valve size.

216B 1 1/2" Angle/Globe Valve

HPV100G 1 inch Globe Valve (Threaded) TxT

globe valve is a valve in the direction of flow. By the side of the valve with the arrow indicating the direction of flow of the fluid that flows through it and out of it. Of the structure of the valve shown in Figure 2 can be seen that the liquid flowing through the valve will swerve several times, even if the valve is fully open it. The pressure drop across a globe valve above the gate valve to close - open the valve is closed - open the disk (the disk or disc is the same) or plug is placed in alignment with the direction of flow. (In the direction of flow is from left to right) with openings that are aligned with the direction of flow as well. When the fluid flow into the valve body. Fluid will be forced to swerve to the bottom and top. Flow through the spaces between the openings on the disk / plug the size of the gap by moving the disk / plug up - which on a disk / plug the rise. Space is more open. Fluid will flow faster.

B and K Industries 106-004NL 3/4-Inch Low Lead Globe Valves

The relationship between flow rate of fluid flow through the valve with the motion of the disk / plug depends on the design shape of the opening and the bottom of the disk / plug the disk / plug that does not require any form. a flat plate. May have a curved or conical cutting head or head to form any time by using the proper format, we were able to valve relationship between flow rate and distance of motion of the disk / plug in various forms. as a straight line. (That is, if the valve open 20% of the fluid is flowing at a rate of 20% of the maximum flow rate if the valve open 65% of the fluid is flowing at a rate of 65% of the maximum flow rate) or a valve that rate. The flow is almost full when the valves open for a little time. (When the valve is opened slightly. Fluid to flow through the valve with high flow rate is almost double the maximum flow rate. When the valve opens up further. Flow rate did not increase much because it is near the maximum flow rate) globe valve is a valve for adjusting flow rate.

From Figure 2 it can be seen that the pressure of fluid acting on a disk / plug it in the direction of motion of a disk / plug that is located in the axis of the shaft valve (stem) of the valve through the stem valves. to a disk / plug is attached to the seat of the openings (the seat is a soft material over the disk / plug to provide a secondary disk / plug close to the seat to prevent leakage. (That is, to act as a gasket), and also prevents the disk / plug is damaged when it is pressed to attach to the skin opening) is not the pressure of fluid in the pressure plate disk / plug to attach to the seat just in case. The gate valve is why the pressure on the upstream and downstream are very different when the valve closes the opening of globe valve is easier than opening a gate valve, and by relying on competitive pressure plate disk is attached to seat them. The globe valve is closed tightly over the gate valve (as long as the surface of a disk with a seat to no damage).

A globe valve are designed to provide a disk / plug is firmly attached to the valve stem. I rotate them. This is to a certain position of the disk / plug exposed to the same location on every time the valve seat. In order to make a disk / plug itself has to wear a uniform. (Just as we need to switch the tires on a 10,000 km run to me. I know that I ever noticed it or not. Right-powered car steering wheel. (Most of our cars) right side tire will wear faster than the other wheels. Front tire and will wear faster than the rear).

Disadvantages of a globe valve in addition to having a high pressure drop. The size and weight of the valve is greater than that of the gate valve globe valve is the larger size and heavier as well. For this reason, in the case of pipes, large pressure on the upstream and downstream are a lot of the globe valve size will cause a pressure drop in the pipe and having a base of the valve that is stronger than a gate valve or the case. the hot fluid. (Ie piping, steam) at the downstream of the pipe is cold, which in the beginning to gradually warm the pipe on the downstream, the heat up slowly to prevent thermal shock or water hammer (in the case of fuel, water), made possible by to gradually open the valve at least once (crack open) until the tube starts to heat up. And increments it so that the flow control at this scale, a large globe valve be bad. The solution is done by using a gate valve in the closing - the main pipeline. (Such as a main pipeline with 12-inch) and a globe valve is in the pipeline bypass, which is smaller than the main pipeline (the pipeline bypass may have a 1-inch) and indirectly through a gate valve to be as shown in Figure 3, when The open tube will begin to gradually open the globe valve on the pipeline bypass is when the pressure or temperature in the downstream is the appropriate level, then it will open a gate valve that is located on the main pipeline and close. globe valve on the pipeline bypass.

In the case of a solid mixed with other fluids. Solid residue on the surface, it may cause problems, globe valve seat is not completely closed, such as gate valve.

Figure 3 is a globe valve in the bypass pipe to assist in opening a large pipe with a pressure / temperature in the downstream and upstream c are very different.

0 ความคิดเห็น:

Post a Comment